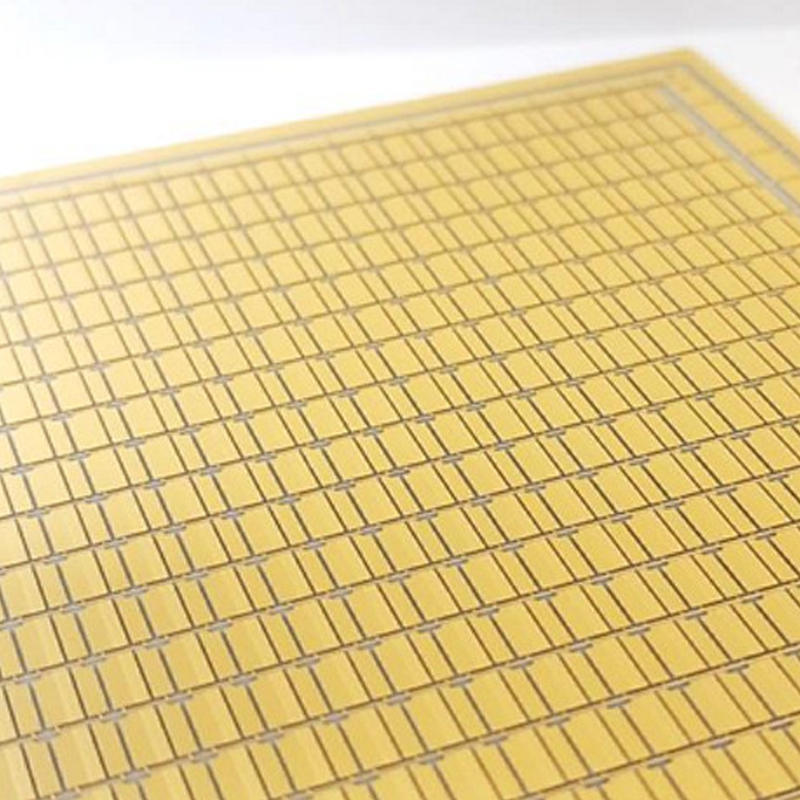

The emergence of advanced heat dissipation substrates originated from the increasing inadequacy of traditional printed circuit boards (PCBs) and thick-film alumina substrates in meeting demands for advanced heat dissipation capacity, circuit precision, current-carrying capability, and reliability.

As electronic components operate, the generated heat requires more efficient conduction pathways to address the issue of waste heat accumulation during electrical-to-optical conversion, which shortens service life. Concurrently, finer circuit patterning is essential to interconnect increasingly miniaturized, high-density chips.

Application Description

Advanced heat dissipation substrates emerged to address limitations of traditional PCBs and thick-film alumina substrates in high-power, high-density electronics. As devices miniaturized and performance increased – particularly in electro-optical applications like high-power LEDs and laser diodes – ineffective advanced heat dissipation caused temperature spikes, reducing component lifespan and compromising reliability.

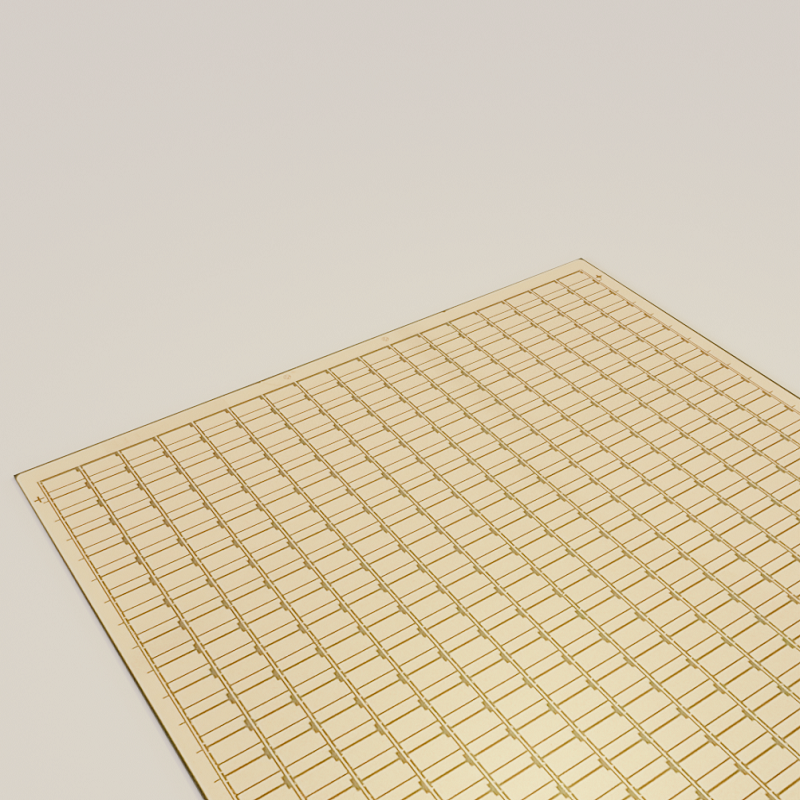

Key Advantages of Advanced Heat Dissipation Substrates

1.Enhanced Thermal Management: High-thermal-conductivity materials rapidly transfer heat to heat sinks.

2.Fine-Pitch Circuitry: Advanced processes (thin-film/DPC) enable high-density chip interconnects.

3.High Current Tolerance: Robust metal layers support power-intensive operations.

4.Improved Reliability: Effective thermal control extends device lifetime.

Critical Applications

1.Industrial Lasers

- Application Examples: Cutting/welding systems

- Substrate Role: Prevents wavelength drift & failure in AlN-based substrates

2.Optical Communications

- Application Examples: 5G/data center transceivers

- Substrate Role: Maintains signal integrity in high-speed lasers

3.Sensors

- Application Examples: LiDAR/3D sensing

- Substrate Role: Ensures thermal stability for measurement accuracy

4.Medical

- Application Examples: Surgical/ophthalmic lasers

- Guarantees operational safety through consistent thermal management

Lincotec provides high-performance advanced heat dissipation substrates with custom manufacturing and co-development services tailored to industrial laser, optical communication, sensor, and medical applications.