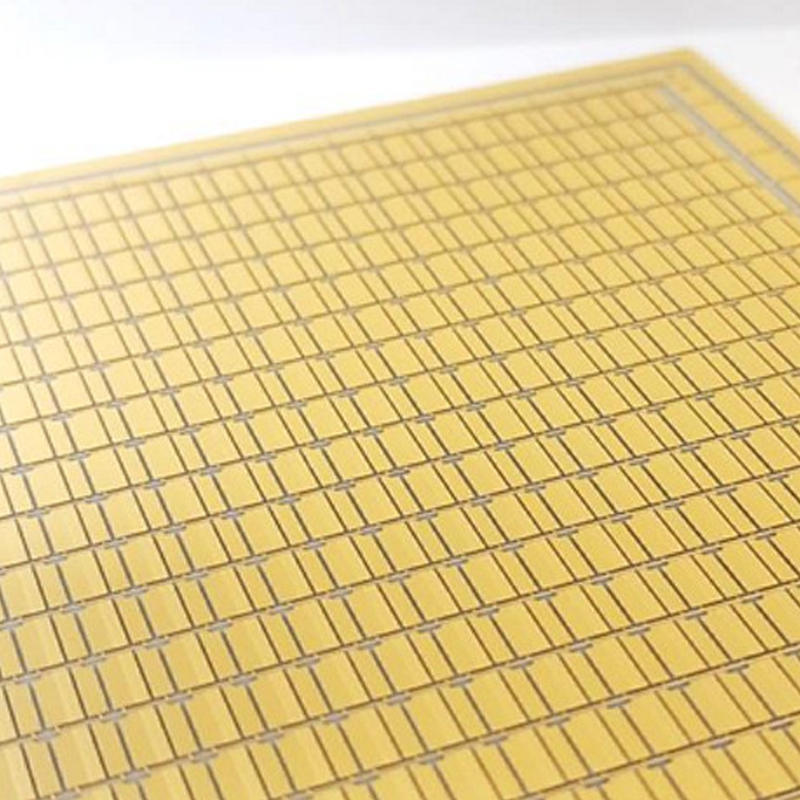

Non-Plating Line (NPL) Plating Technology offers a method that doesn't require the installation of plating wires on the substrate's surface. It allows for the electroless nickel-gold plating of contact pads at the edge of the substrate. The main approach involves using a conductive film as the current conduction path to connect various contact pads on the substrate, enabling the electroless nickel-gold plating and structure. This significantly reduces the impact caused by the installation of plating wires.

Application Description

Non Plating Line (NPL) or thin copper plating technology offers a method where it's not necessary to place plating wires on the surface of a substrate. Instead, it allows for the selective plating of nickel-gold on the contact pads at the edges of the substrate. This technology primarily utilizes a conductive film as the path for electrical conduction to connect the various contact pads on the substrate, enabling the electroplating of nickel-gold.

The circuit configuration using the NPL process doesn't require additional plating wires on the substrate surface. This leads to a reduction in the substrate size and wire material. It not only facilitates circuit layout but also prevents noise caused by redundant plating wires during high-frequency usage, resulting in improved performance.

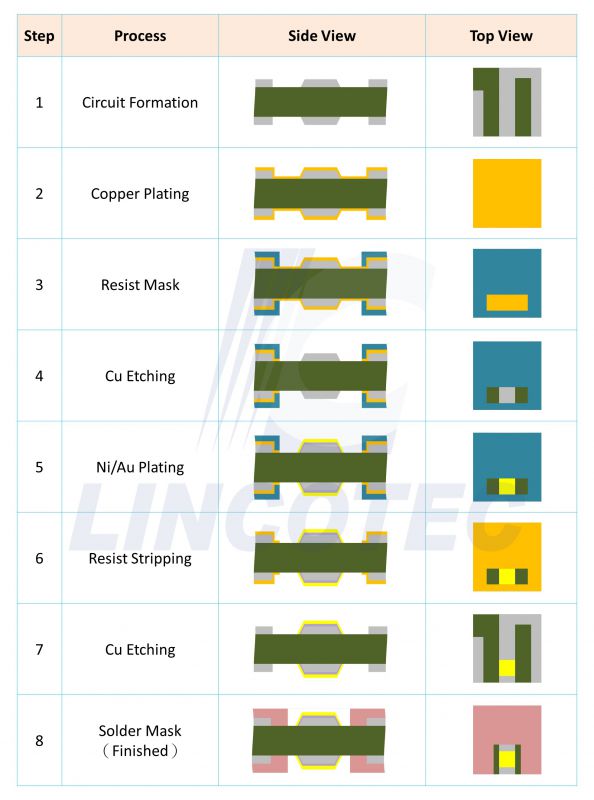

Referring to the descriptions in the relevant patents by Quanmao Electronics (merged into Unimicron in 2009), the NPL process is generally as follows:

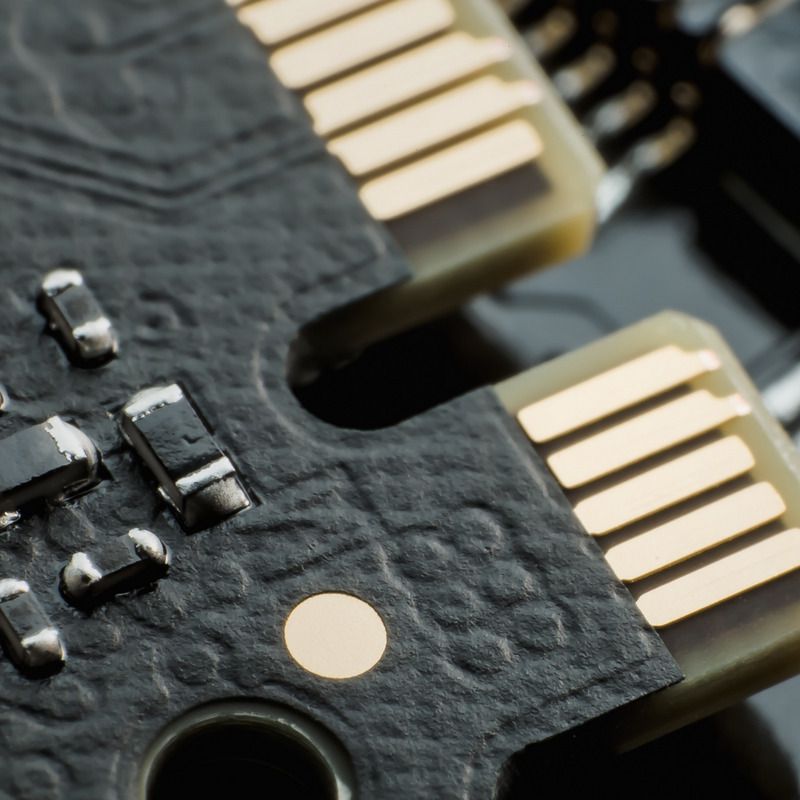

In this regard, Lincotec possesses proprietary intellectual property and holds key process technologies, such as adhesion of coatings, coating uniformity, edge film thickness, coating resistance, control of substrate surface temperature, Cpk, UPH, target material utilization rate, selective etching, and etching uniformity, etc. Furthermore, the company can integrate both front-end and back-end processes to control process parameter characteristics and provide excellent processing performance and stable reproducibility. Lincotec has rich intellectual property in process validation and has qualified, highly precise laboratories for sample testing, enabling collaboration with customers in process development and experimental validation.