Roll-to-roll vacuum sputtering equipment processes continuous coating of flexible substrate materials in roll form using techniques like PVD or CVD. With plasma surface pretreatment, adaptation of various process parameters like gases, temperature, power, and time, uniform and high-adhesion film layers are formed.

Lincotec possesses advanced, oil-free, low-energy, high-vacuum systems, employing high-efficiency, high-density plasma sources to meet the diverse needs of different substrate materials. In addition, high-efficiency rotary cathodes and special substrate cooling modules enable high-throughput and stable production of ultra-thin flexible substrates with excellent coating capabilities.

Application Description

Roll-to-roll (R2R) thin film material sputtering refers to the continuous deposition of thin films on flexible and lightweight substrates, such as polymer films (e.g., PET, PP, PI films), metal foils, or flexible ultra-thin glass. This process involves rolling these materials into coils and placing them into vacuum sputtering equipment, utilizing either Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) processes for continuous coating. Prior to deposition, various preprocessing steps like plasma surface modification are performed, and parameters such as gas ratios, vacuum levels, process temperatures, ion bombardment power during sputtering, and deposition times are carefully controlled to achieve uniform and strongly adherent coatings.

This application is widely used in various industries, including copper foil for lithium-ion batteries, flexible printed circuit boards (FPCBs), Indium Tin Oxide (ITO) coatings, Anti-Reflection Coatings (AR coatings), Flexible Displays, and Flexible Solar Panels. It is employed to create different layers like conductive layers, optical layers, barrier layers, adhesion-promoting layers, or dielectric insulating protection layers etc. Common sputtering materials include ITO, Au, Ag, Cu, C, Ti, Ni-Cr, and thers. Below is further introduction:

一、R2R Film Sputtering Application in Lithium Batteries:

With the expansion of the electric vehicle (EV) and energy storage systems (ESS) markets, effectively reducing the thickness of the copper foil used in the negative electrode current collectors of lithium batteries is crucial. This allows for the placement of more copper foil layers within a limited volume, enhancing energy density. Additionally, addressing safety concerns related to volume expansion and contraction during the charge and discharge processes of lithium batteries becomes a key competitive factor. In response to these demands, composite copper foil materials such as "copper-polymer material-copper" with core materials like PET/PP/PI have emerged.

In this structure, the thickness of the copper layer is significantly reduced compared to traditional copper foils. Consequently, more copper layers can be accommodated within a single battery, leading to an increase in energy density. Moreover, due to the thinner copper layer and the excellent flexibility of polymer materials, the risk of internal short circuits is greatly reduced, even if the battery fractures under pressure, as the thinner copper fragments are less likely to pierce through the polymer material.

二、R2R Film Sputtering Application in Flexible Printed Circuit Boards:

The manufacturing process of flexible printed circuit boards (FPCBs) involves bonding flexible copper-clad laminate (FCCL) and cover layers (Coverlay). Laser perforation, copper plating, etching, lamination, and surface treatment processes are then used to create circuits for electronic signal transmission on the circuit board. FPCBs offer advantages such as lightweight, thinness, flexibility, and the ability to reduce product volume. They can be shaped into three-dimensional wiring configurations, improving system wiring density and reducing wiring errors. These boards are widely used in consumer electronics, industrial applications, military products, medical devices, automotive, and related applications. The metal layers produced through vacuum sputtering processes enable precise control of thickness, high adhesion, and a dense structure, resulting in superior low-resistance performance.

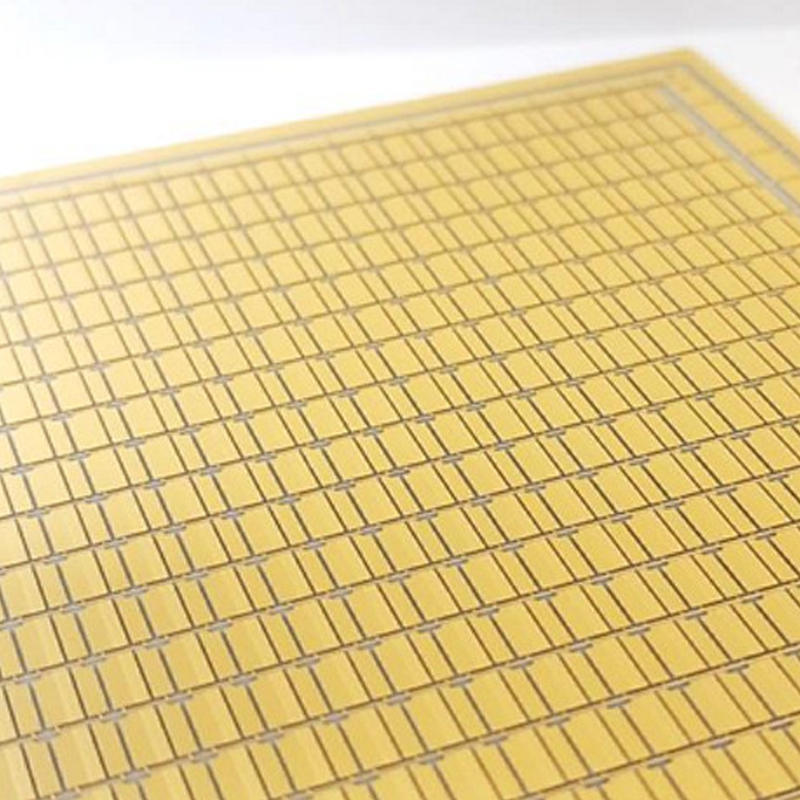

三、R2R Film Sputtering Application in Touch Panel Metal Mesh:

Touch displays for consumer electronics must balance transparency and capacitive sensing. Existing ITO films are limited in their use for medium to large-sized displays, leading to the development of transparent and flexible conductive metal mesh films. Metal mesh films are created by depositing metal layers on PET substrates using R2R sputtering equipment, followed by patterning the layers through photolithography. The resulting metal mesh film achieves a light transmittance of over 90%, meeting the transparency requirements for touch panels.

四、R2R Film Sputtering Application in AR Anti-Reflective Coatings:

Reducing surface reflections on glass through coating technology increases overall spectral transmittance. This is commonly seen in energy-saving films applied to building glass to enhance indoor air conditioning efficiency and increase privacy. AR anti-reflective coatings, manufactured using R2R film sputtering equipment, typically consist of multiple layers of optical design films deposited on a PET film base. These layers include high-refractive-index TiOx, low-refractive-index SiOx, and a silver alloy heat-reflective layer, achieving high light transmittance, high absorption of solar UV radiation, low thermal infrared emissivity, and high electrical conductivity.

In this regard, Lincotec holds independent intellectual property rights, has extensive process development experience, and collaborates with customers for process development and experimental verification. In addition to providing sampling services during the R&D stage under different process formulations, the company also has qualified and highly precise laboratories for sample testing.

Lincotec Features

Superior coating quality, precise control of winding and unwinding, achieved through advanced roll-to-roll sputtering equipment for big data quality and process monitoring.

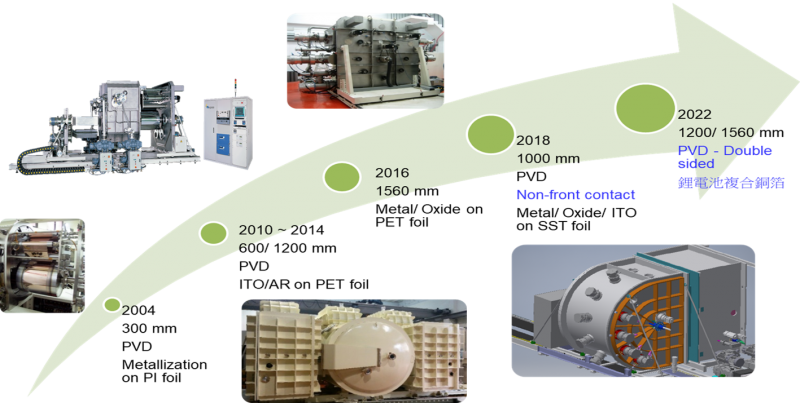

Achievements