每個電子元件或其系統在運作時都會產生一定程度的電磁干擾 (EMI),這會對周邊電器的性能產生不利影響。因此,電子元件或其系統的電磁干擾必須受到限制,同時,對環境中的干擾也必須具有足夠的免疫力。

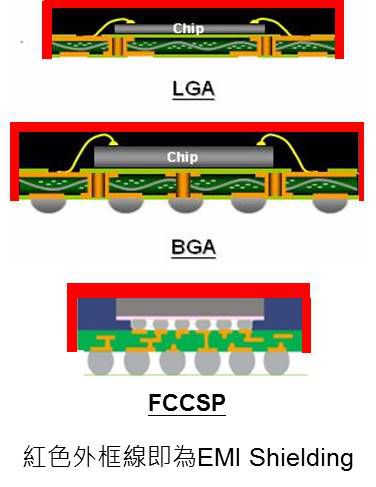

「抗電磁干擾屏蔽濺鍍」即是以乾式製程於電子元件的外表面以物理的方式附著上足夠厚度的屏蔽層,藉此達到電磁屏蔽的目的。

應用說明

「抗電磁干擾屏蔽濺鍍」是於電子元件的外表面披覆足夠厚度之金屬層,藉此降低電子元件對外界產生電磁干擾,亦避免外界的電磁進入內部而影響電子元件的運作。大部分的國家對於電磁標準制定了明確的認證制度,且多是基於國際電工委員會(International Electrotechnical Commission;IEC)所訂定的EMC(Electromagnetic Compatibility ;電磁相容性)標準。

IEC官網對於EMC有以下的說明:

「Every electrical and electronic device produces a certain level of so-called electromagnetic interference (EMI) that can adversely affect the performance of similar equipment located nearby.

Electromagnetic compatibility (EMC) provides methods that help contain EMI so that electrical and electronic systems or components are able to work correctly even when they are close together. In essence, EMC is about protecting sensitive equipment such as radio receivers, domestic appliances or electronic circuits from electromagnetic interference, and containing the electromagnetic emissions for example from large scale batteries, power lines or electric motors so that they can't interfere with more sensitive devices.

Multiple sources of electromagnetic disturbances can have a cumulative effect on a device. For example, the emissions from several laptop computers combined with those from mobile phones could disrupt systems in an aircraft.

The electromagnetic disturbances from each item of equipment must be limited and, simultaneously, each item must have an adequate level of immunity to the disturbances in its environment.」

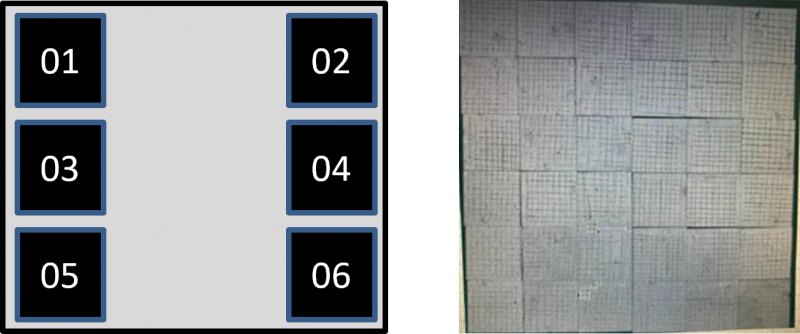

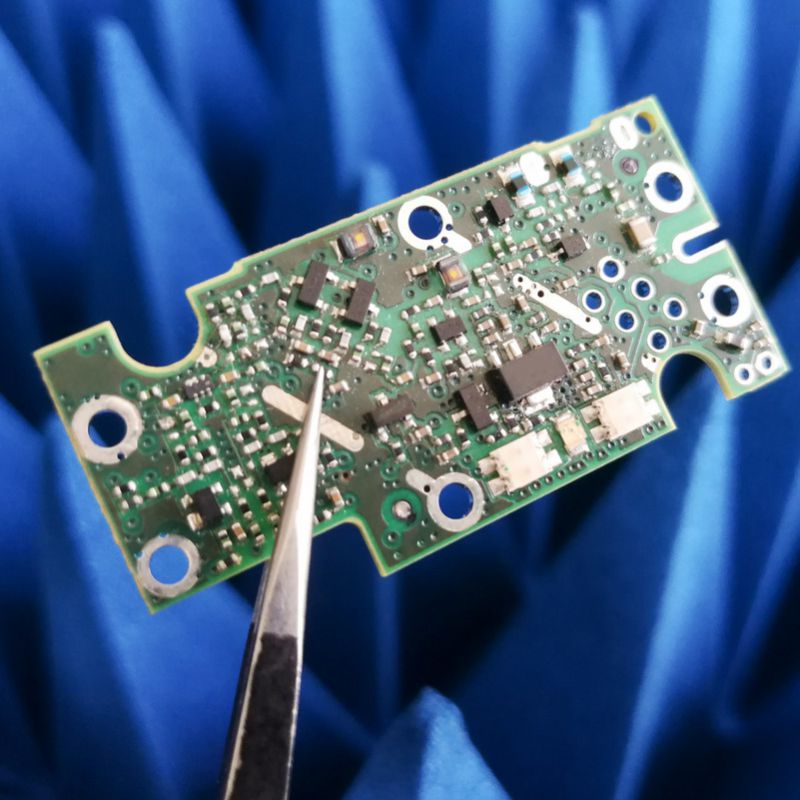

一般而言,用於軍工或太空領域中的設備或電子系統有嚴格的可靠度要求,而即使是例如智慧型手機、電視、有Wifi或藍芽的數位相機等具通訊功能的消費型電子產品,除了於其外殼進行抗電磁干擾屏蔽以符合前述的認證規範之外,為了降低不同晶片或電子元件之間因電磁干擾而產生的錯誤運作,還需進一步針對各晶片模組進行屏蔽。例如分別對WiFi模組、Bluetooth模組、RFFE(RF Front-end;射頻前端)模組、PMIC(Power Management IC;電源管理晶片)模組等進行抗電磁干擾屏蔽。

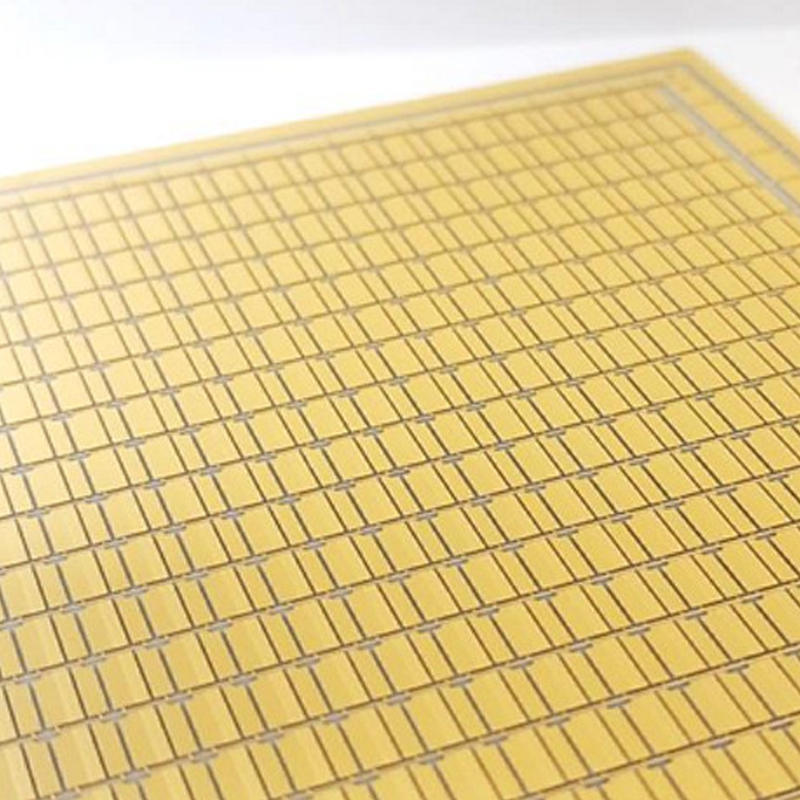

而濺鍍(Sputtering)製程設備屬於物理氣相沉積(Physical Vapor Deposition;PVD)的技術運用,能在真空環境及較低的溫度下以物理方式製備出高熔點材料的均勻薄膜鍍層。尤其當晶片日趨微小且各廠致力於縮小相鄰電子元件之間的間距時,於SiP(System in Package;系統級晶片封裝)製程階段即導入抗電磁干擾屏蔽濺鍍設備,並以乾式的物理方式於電子元件的外表面附著上足夠厚度的屏蔽層,將是最具有產能及環保效益的選擇。

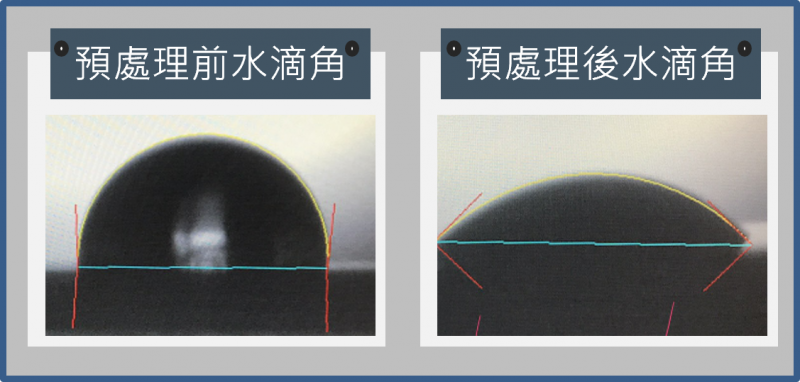

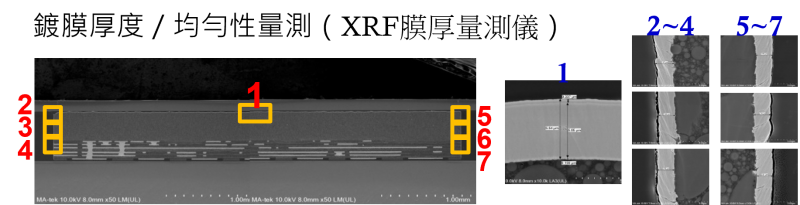

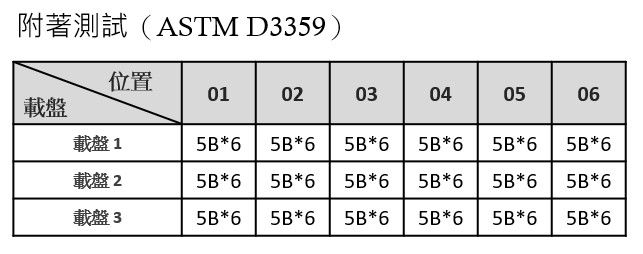

對此,抗電磁干擾屏蔽濺鍍設備的製程驗證至少包含:附著測試、膜厚均勻性量測、側邊膜厚量測、鍍膜阻值量測、待鍍物表面溫度限制、Cpk、UPH、靶材利用率等。進一步還需整合前後段製程,以掌握待鍍物的參數特性,並提供優異的加工表現及穩定的再現性。凌嘉科技對於前述製程驗證有豐富的智慧財產權,並擁有合格且高精密度的實驗室能進行樣品的測試,協同客戶進行製程開發及實驗驗證。

凌嘉特色

世界知名手機大廠(Tier 1)指定的EMI濺鍍設備

實績